Long hours of post-production, studio filming, client walk-ins, and spontaneous meetings. These are just a few of the challenges a film production company, like Mighty Fine, deals with on a daily basis. Our approach was to meet all the demands of a creative lab but to add a sense of style and comfort, qualities indicative […]

Tag: plywood

Raw bringing it in with Inhouse at 100% Design 2019

There are a few things that keep us motivated here at Raw Studios… from the smell of freshly made coffee to start our day to exciting new products and projects that energise us and encourage us to grow and push the boundaries. The third motivator is when hard work pays off… This got new meaning […]

Soon we’ll be moving in, but for now we are moving ever forward and upwards…

With 100% Design 2019 behind us and with the overwhelmingly positive feedback received, we are eager to proceed and grow Inhouse into a product which can meet your most important needs. After the launch of Inhouse, Visi interviewed Peet to get the inside scoop. The article will feature in this month’s issue; it’s the perfect opportunity to […]

Designers and innovators on fire at 100% Design 2019

Photo credits: SA Décor Missed out on who the epic designers were that took home the awards at 100% Design 2019? → After the judges diligently made their rounds through all the stands at 100% Design it was time to announce the winners. The awards evening took place at the Clout café designed by Studio […]

Creating furniture is one thing… but creating place, now that is where it gets exciting

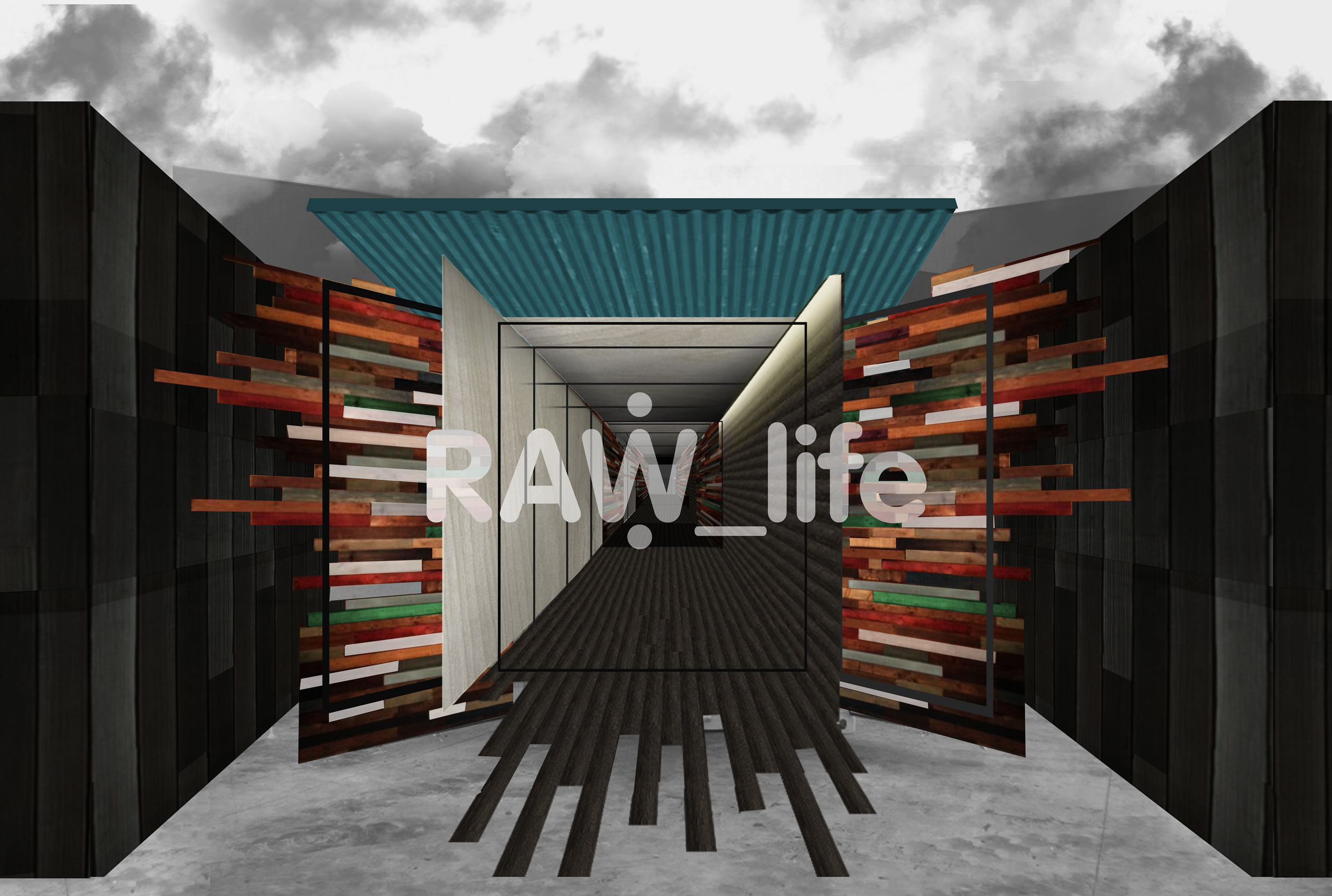

People usually expect big things from Raw Studios at 100% Design and this year, as always, we won’t disappoint. In addition to our collaboration with the curators to create a space for interesting workshops and talks we have been developing a range of sustainable and affordable timber frame buildings and homes that are flexible, adaptable, […]

Raw Studios is much rawer than expected

Earlier this year Peet was given the opportunity to talk about his journey with Raw Studios at the Pretoria Institute for Architects’ Ideas Conference. With 13 years in the making, multiple ranges and 100’s of products available, 45 minutes was just too short to give a complete picture, so we made a short video to […]

Crafting furniture to live in, literally…

We took our knowledge of furniture design, engineered materials and CNC manufacturing and applied it at a much larger scale to start creating our new range of furniture you can live in. Nestling is a work-in-progress micro-living container and the beginning of something much bigger. Crafting the container also led us into developing a modular […]

Time to live differently. Our 5 ways to design to a different tune.

Companies and designers have to keep challenging their designs to remain contemporary: a challenge that requires alternative approaches and thinking. With some insight into what RAW is up to, here are our top 5 ways to get in tune with ‘different’: 1. Have an opposite day. Used to tackling your design process in a specific […]

The countdown has started… The world is coming to Africa.

Imagine an existing space where human, space and object are intertwined, where interaction is a core aspect of creating synergy between humans and their environment. Well, stop imagining because this concept is already in the making at the Future Africa Institute, a campus for international students aimed at creating a holistic and interactive environment. Earthworld […]

Confessions of our latest RAW member.

This Visi magazine featured designer reveals her 4 funniest experiences being new to furniture design and RAW. 1. Avoid stereotypes. On my first visit, I expected a grimy old chaotic workshop full of mounds of saw dust , furniture parts scattered everywhere and sad fluorescent lights flickering overhead. To my surprise Raw Studios was the […]